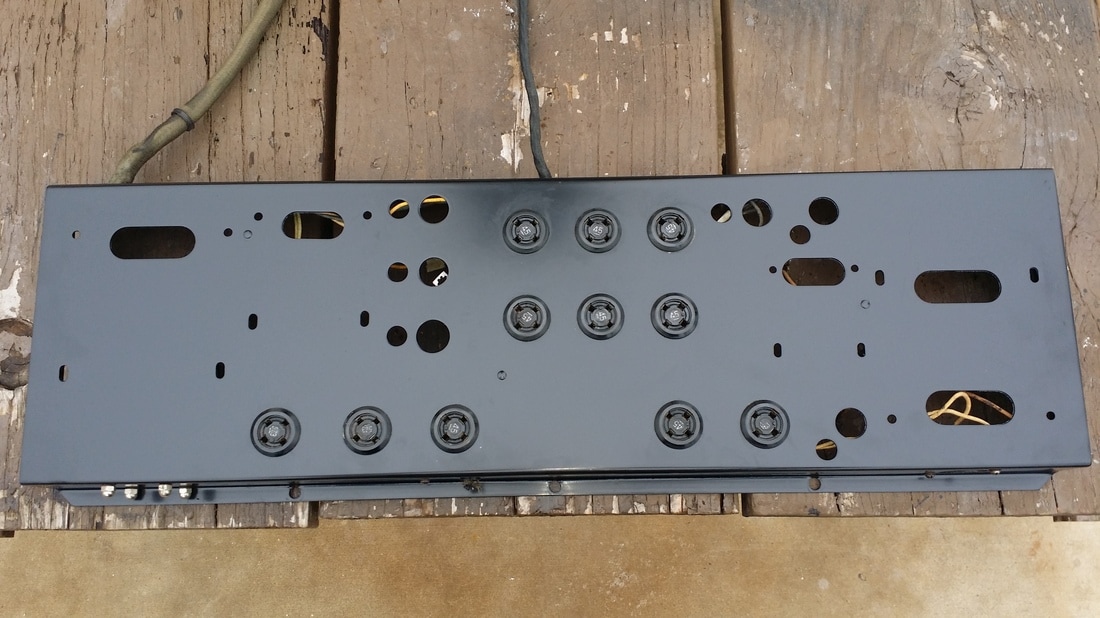

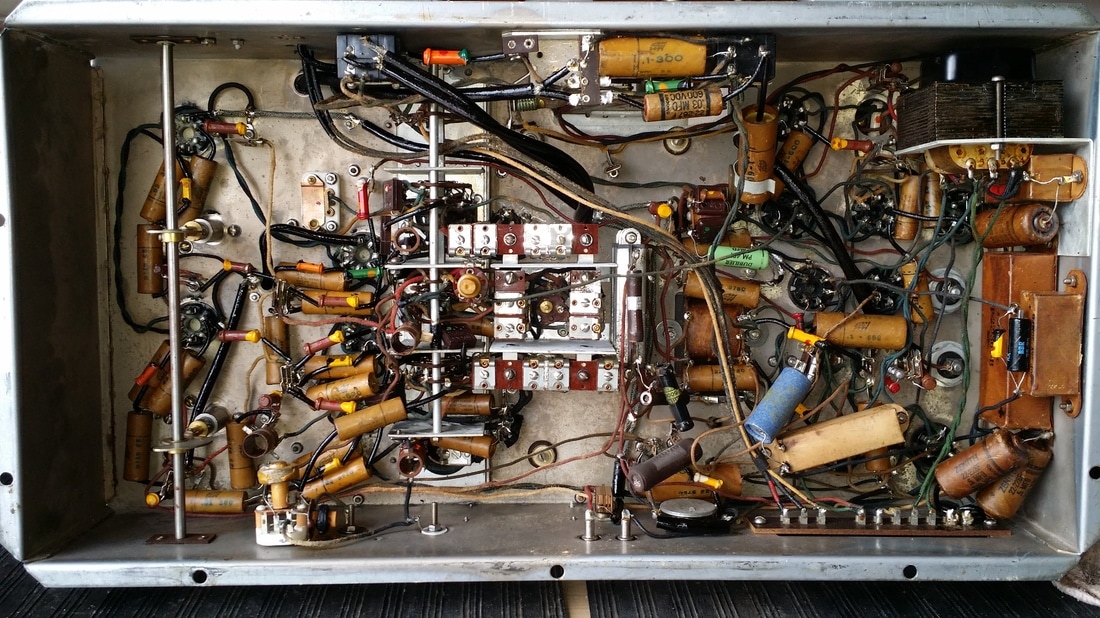

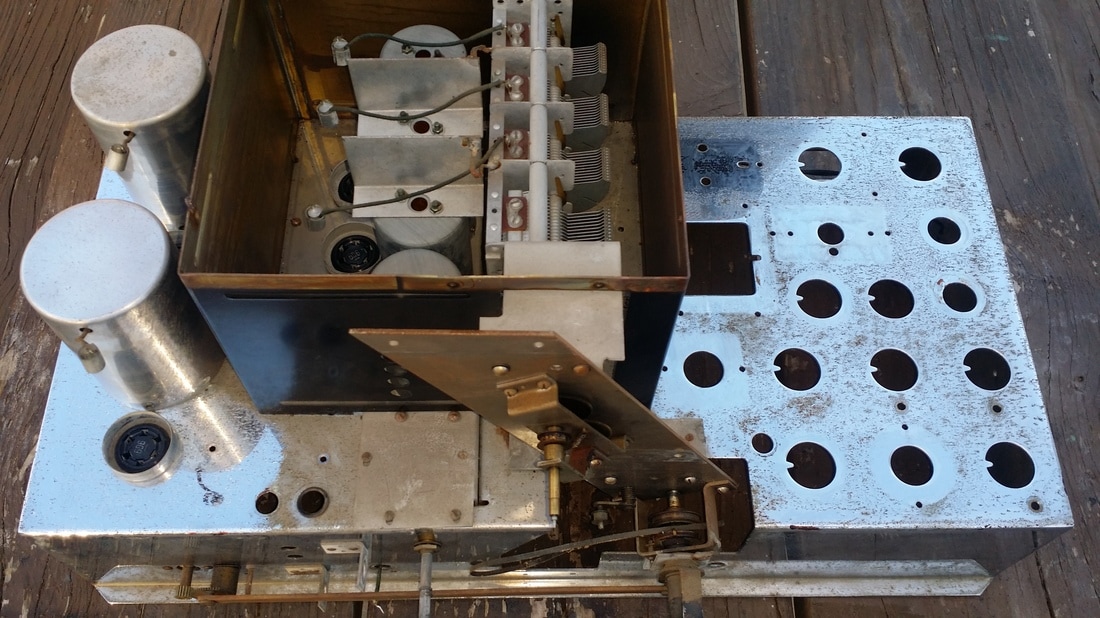

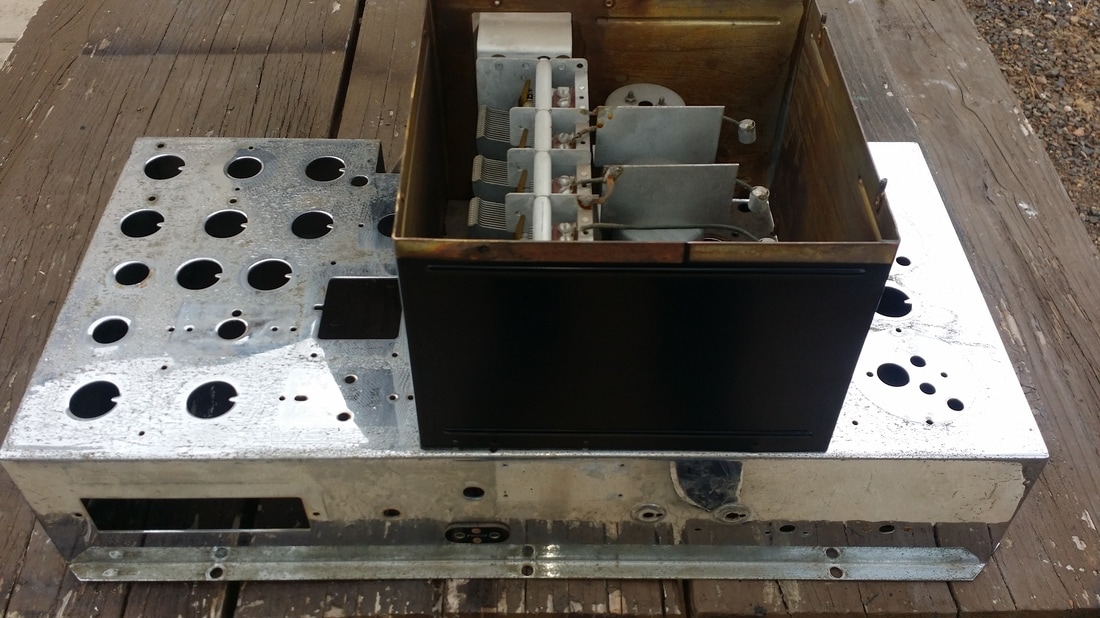

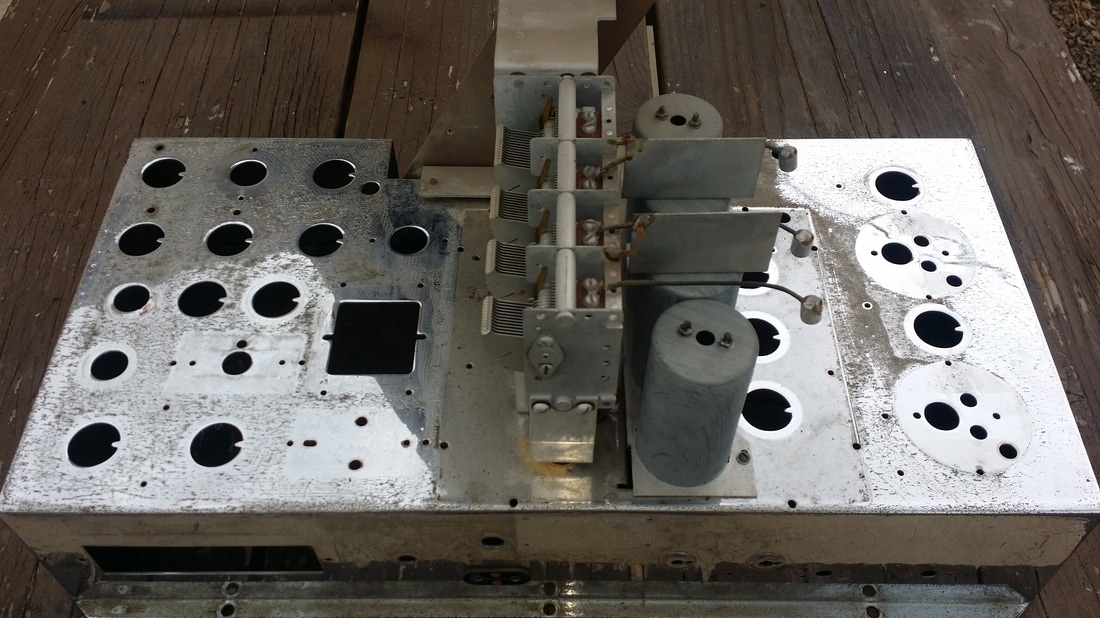

Below is the sort-of before picture. Work was started on this chassis prior to my involvement. It is shiny metal since the paint has been partially removed by wire brush. The filter caps were removed and cut open. The power/signal cable to the receiver chassis has had the connector cut off. Having done one of these before, these issues should be easy to resolve with the objective being reliable operation with an original appearance.

I am going to replace parts as needed before remounting any of the iron. It is easier to work on the chassis while it is 20lbs lighter.

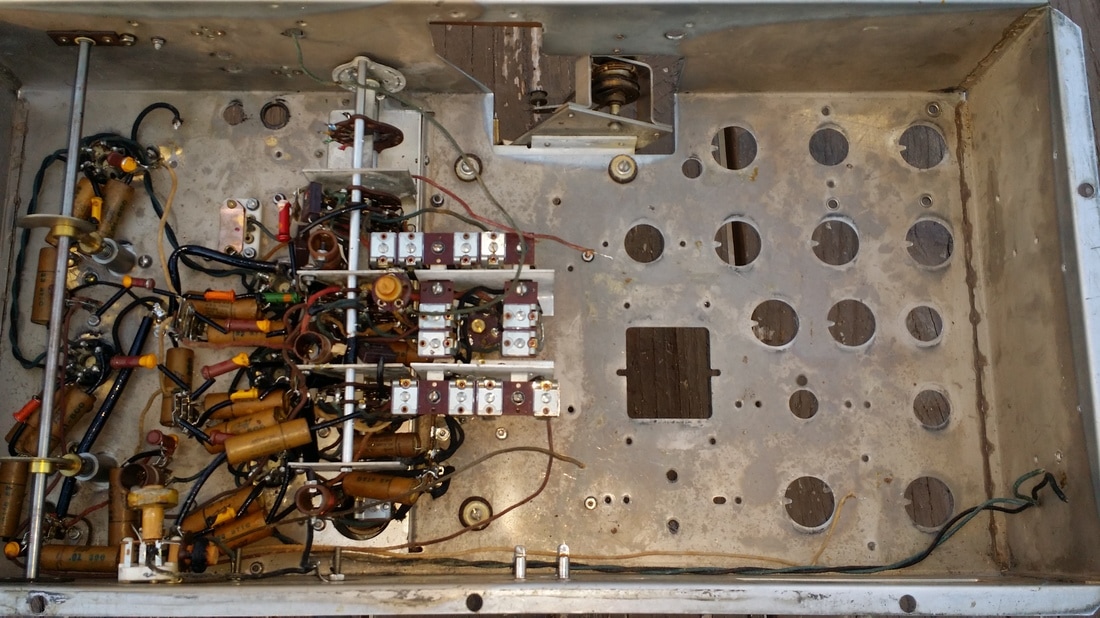

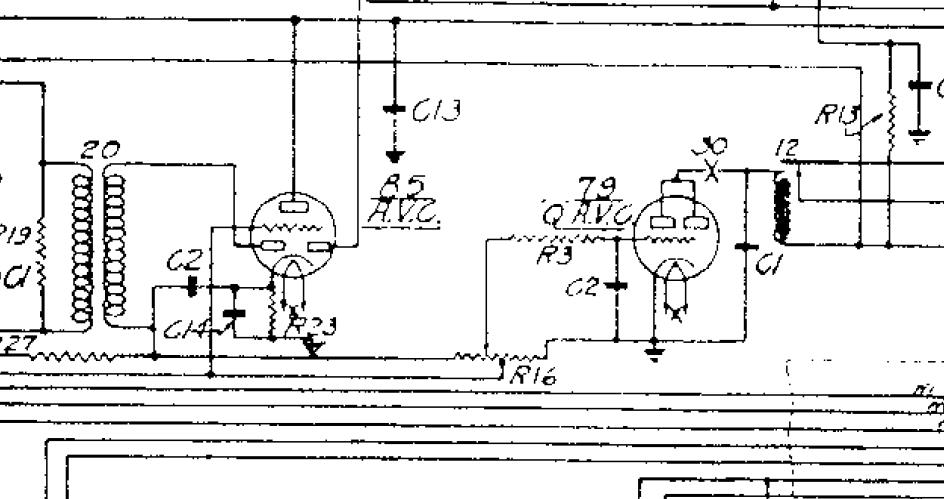

On this chassis these cathode resistors are 2 different sizes (watt rating). On the other chassis I restored they were all 1/2 watt.

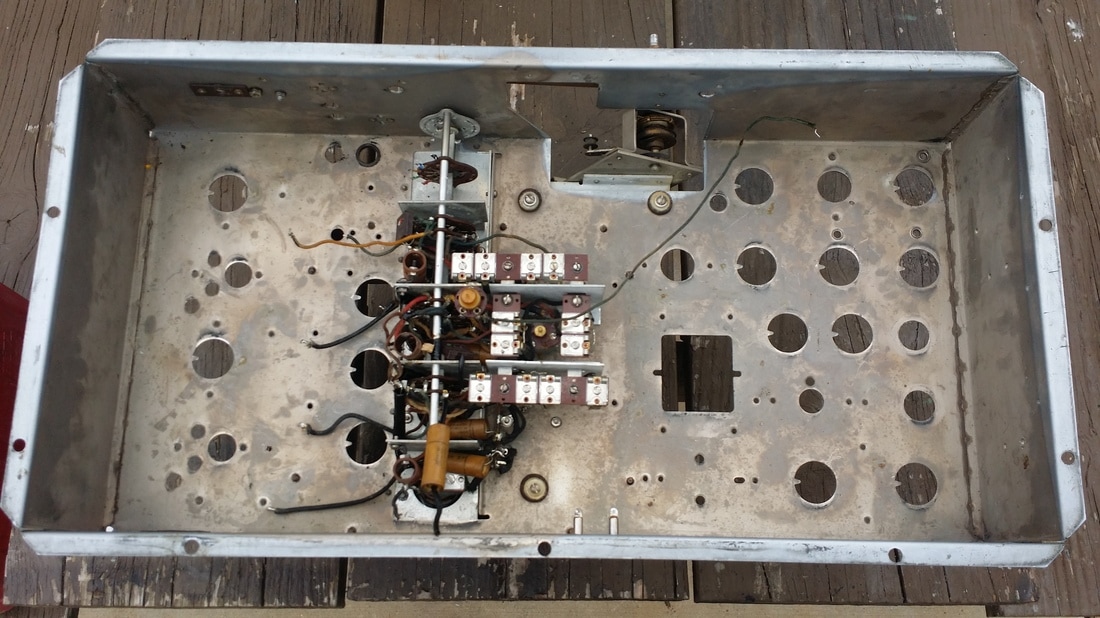

It is time to start on the filter caps.

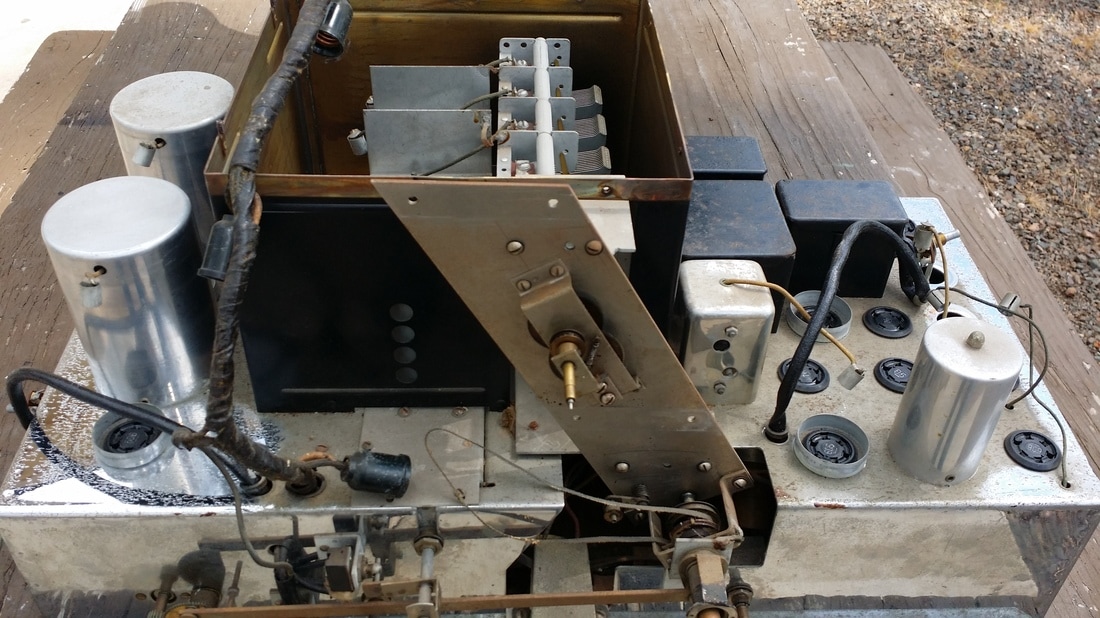

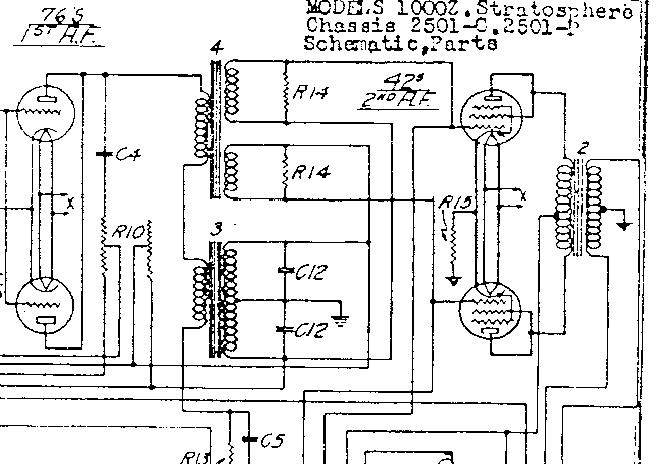

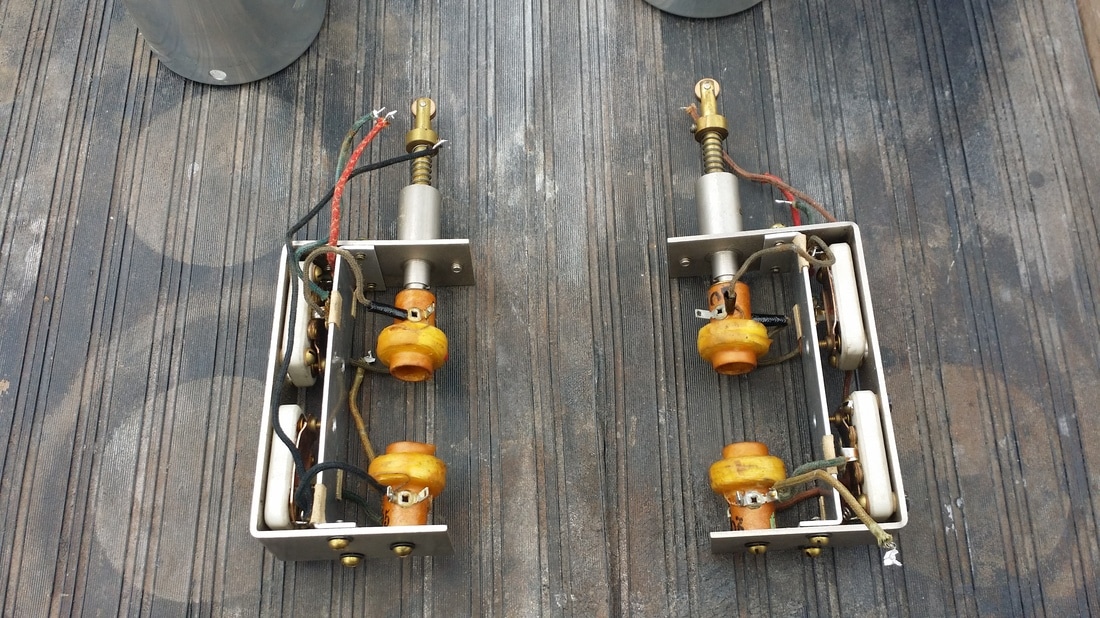

These were all early electrolytics. The design seems to be Sprague's attempt to copy and improve on the Mershon "wet" electrolytic can. There seems to be two or more versions used in the 1000Z. First, a solid copper can with a ground (-) lug incorporated into the isolated base. Then an evolution to the more common aluminum can without a ground lug. The ground lug is accommodated by an additional hole drilled in to the chassis. This extra hole is seen in all of the first 254 power/amp chassis BUT may have been deleted in some of the last 100 chassis produced. The RF/receiver chassis does not have these extra ground lug holes rather using the later version mounting system.

As you can see on the can, It is rated at 600V and 4uf.

The 600V rating poses a challenge for most electrolytic capacitors (even this one failed explosively). Knowing the compromises involved in using electrolytic caps in this position, I chose to use Solen metalized polypropylene instead. These, too, have some disadvantages, size being the most significant. They are, however, rated at 630 volts. I have been using these in place of electrolytics in all applications where they will fit for many years now and have not had a single failure. I anticipate a much longer life as compared to electrolytic caps especially when the electrolytic caps are being operated near their upper voltage rating. An additional advantage is not having to worry about polarity (electrolytic caps are polarized). The other significant disadvantage is cost. The Solens cost about 10 times what a 450V electrolytic cap costs.

The objective in rebuilding these cans is to exceed as much as possible the original voltage rating and to STUFF as much capacity into the can as possible - within the original spec narrowed to about -10% to +150%. So, This 4uf 600V cap is now rated for 6uf 630V (tested).

The larger value filter caps are more of a problem. They have slightly less volume since they were rated for 450V. (The volume of a can is generally larger as the uf rating or the V rating increases. In these caps the 600V rating increases the size more significantly than the lower uf rating decreases it. In other words, the 4uf @ 600V can is slightly larger than the 16uf @ 450V can).

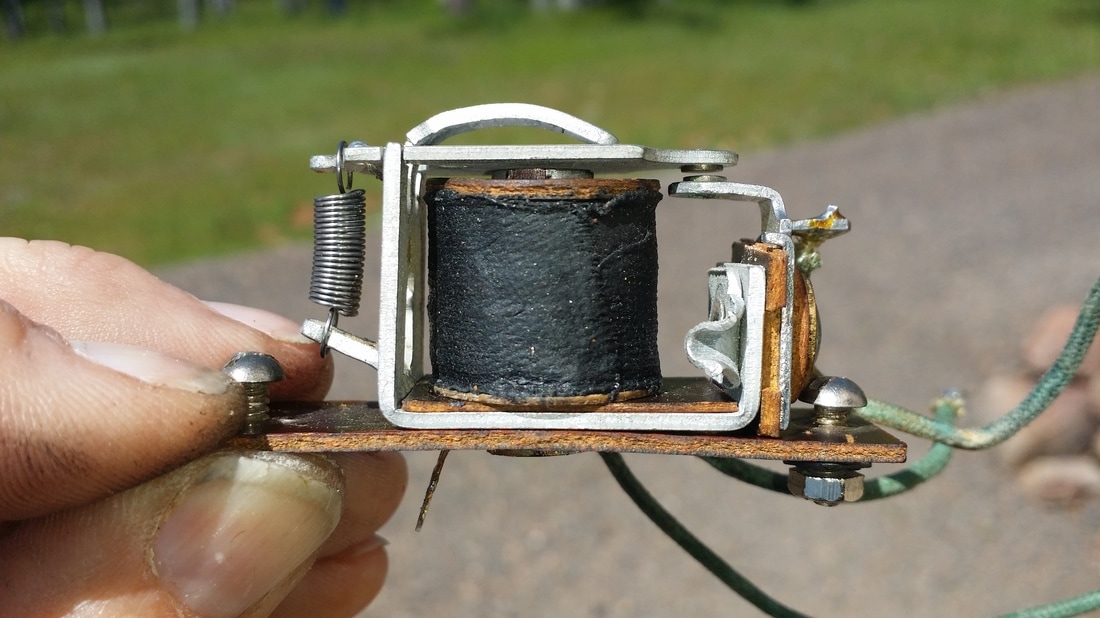

Below: the ground/lug isolation base for the early caps, showing the lead that penetrates the chassis through the 2nd hole. This configuration is not unique to early 1930s radios but this particular part with the dished edges seems unique to the 1000Z.

On the copper can, a ground connection is easily made to the can its self. On the Aluminum cans, I feel safest in extending a ground from within the can to the mounting hardware - not trusting an aluminum solder joint. (See picture 2 above)

Do not paint the lower edge/crimp on the can. It needs to make electrical contact with the mounting hardware.

Yeah, I painted my thumb too. Nice! ;-)

I have decided to rebuild the cable that links the two chassis rather than risk it shorting out.

RSS Feed

RSS Feed