How about a power transformer failure? These things happen, even if it seemed to be OK. Still the HV winding just goes up in smoke. No that's not it either. You can find a transformer and they're not that hard to replace.

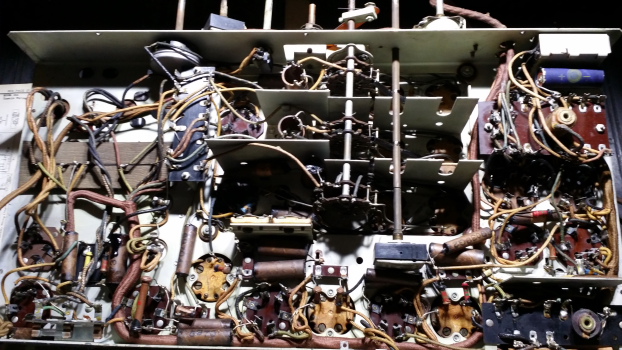

No, the worst thing that could happen almost always sneaks up on you, since you seldom spot a defect until all the work is done (you think!?) Because, even if you've been nice, you haven't pulled on it's wires or twisted it's shaft - with a pair of pliers, a broken band switch is the worst thing that can happen. Or at least most people think so.

If you look and see a broken contact at least you know what is wrong. You know finding another one is unlikely. Though not absolutely true, it seems that the one in every radio is different. And if you were to find one, aren't there about a hundred wires and components hooked to one of those? Even then, the replacement has to survive the operation.

Just the idea of taking a band switch apart is enough to put a radio into the "parts" category. But it's not really that hard ;-) Well, OK, it is hard, but I got a lot of experience while rebuilding the band switch on the 1000Z. I had thought that the wafers on that assembly exhibited bilateral-symmetry (meaning the left is the same as the right or in other words, you can't put it in upside down). I learned the hard way that both of the wafers in the center of the switch could be installed wrong.

So having learned the hard way, it is my conclusion that prior to disassembly a careful study of the switch and the schematic should be undertaken. This will take a while. It is time well spent since you have to identify the problem in the first place.

Most band switches are similar. Basically these allow an operator to switch coils needed for each band all at once. Before these switches a multi band radio had sets of coils that needed to be installed in plug-in sockets. This was OK for a Amateur (ham) operator but a bit much for the general public.

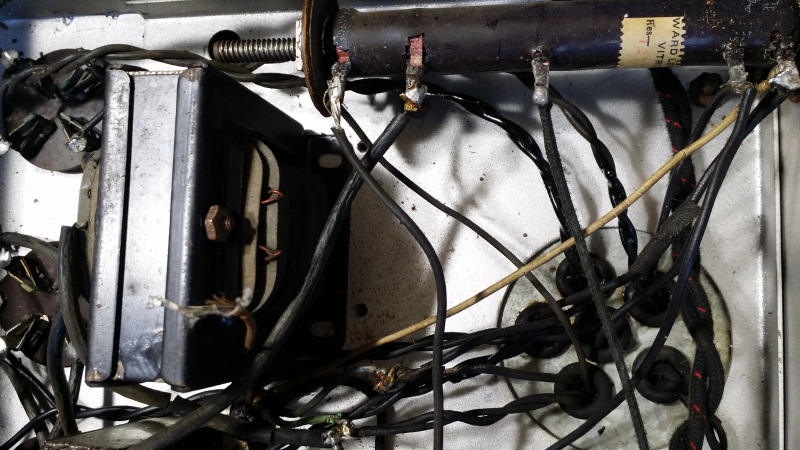

The fixed contacts around the perimeter usually go to the coils and associated components. Below, the 2 contacts circled in yellow are also fixed. BUT there is a hidden contact that slides along under the circular center wafer.

NOTE the index mark at the top! If you want to get these reassembled, index the parts.

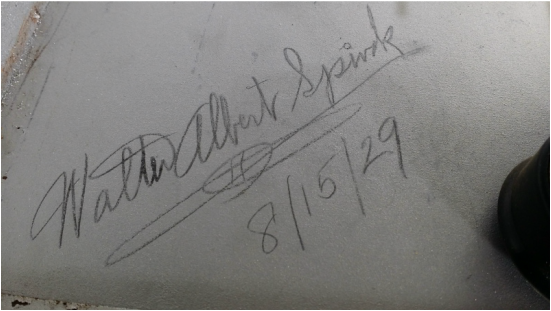

The 12 tube Grunow is now working as it should. I will add pictures of the radio when the cabinet is finished.

Notes about band switch failure:

When de-soldering never overheat the joint or pull hard on a component. The wafer can burn or char resulting in a carbon path (short) or worse a broken wafer or contact. It is often best to cut the component lead and then clean up the eyelet which will help avoid both of these issues.

As mentioned, these switches are designed to travel in a portion of 360 degrees. A five band switch will have more travel than a two band switch. If the switch is forced to move beyond the stops, contacts may be damaged. Look to see that the switch is moving as designed.

Contacts can become oxidized. I use De-oxit (black label) to clean and lubricate. Sometimes a bit of oil on the shaft where it passes through the chassis is needed.

Contacts can become bent. Watch to make sure that the contacts move - just a little - as the switch engages. This will indicate proper contact.

Switches that use flexible wire connections (rare) need to be inspected for broken wire.

Switch position is indicated and maintained by a ball/spring or just a spring/detent. This gives you the click, click as you turn the switch. These can be broken or, in the case of the small ball bearing, it can be lost.

Pressure or twist can put a load on the wafer causing it to warp over time. This may make the switch hard to move or even damage a contact.

Take pictures prior to disassembly and mark parts so that they can be reassembled properly.

Save band switches from "parts sets".

Watch contacts for arcing. Arcing is generally unacceptable in this type of switch and can cause a great deal of damage in a short time. Arcing generally indicates a problem either in the switch or the associated circuit.

A signal "sniffer" can help identify connection problems assuming that the radio is in good enough condition to be operated safely.

Most of all - have patience and good luck..

RSS Feed

RSS Feed