There is still the tree farm to take care of and with the weather changes, 117deg temperatures, drought and or, floods and fire prevention/control, there is still a lot to do. Quite a few large trees have died - free firewood, but that chain saw is getting heavy.

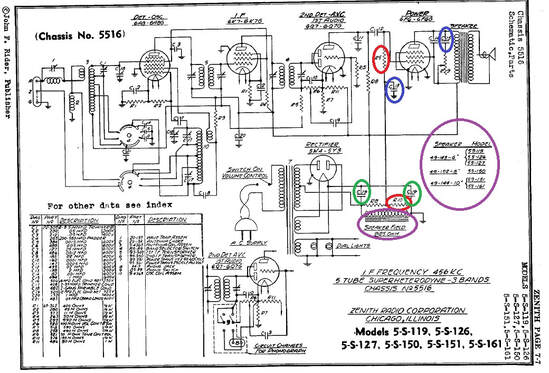

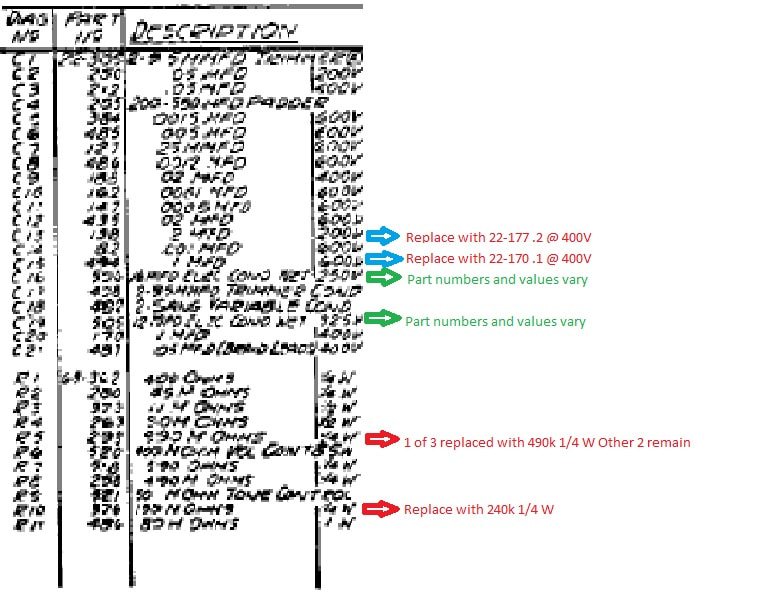

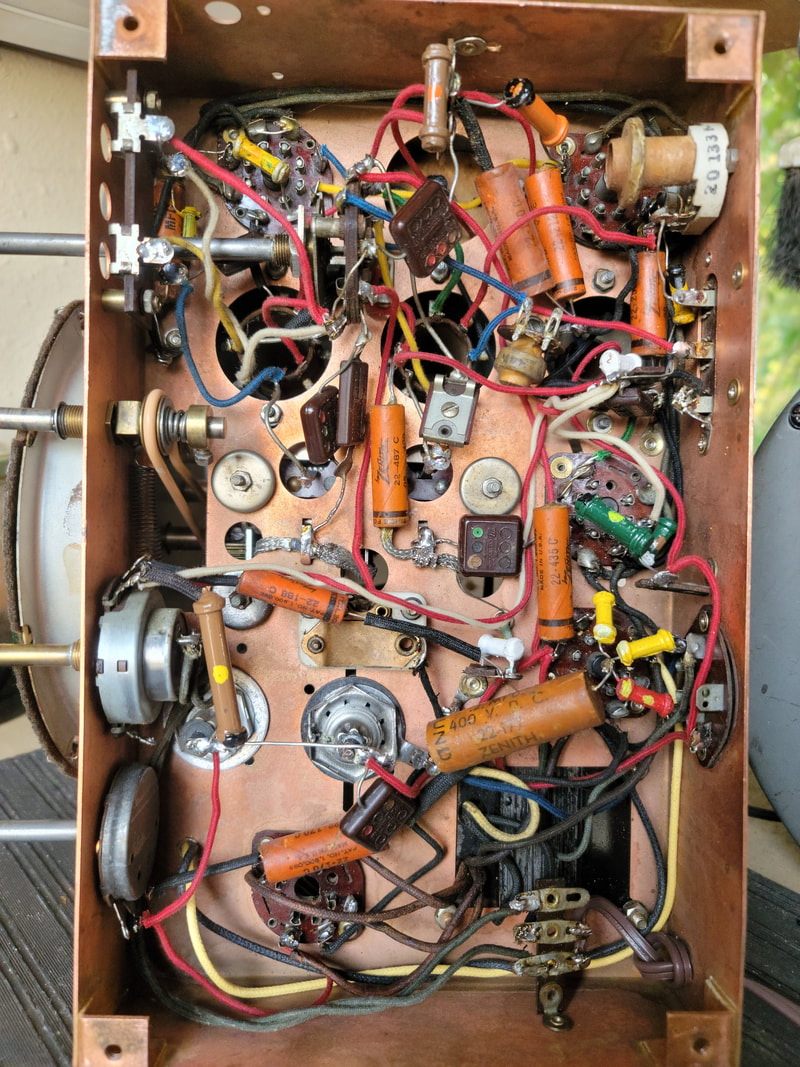

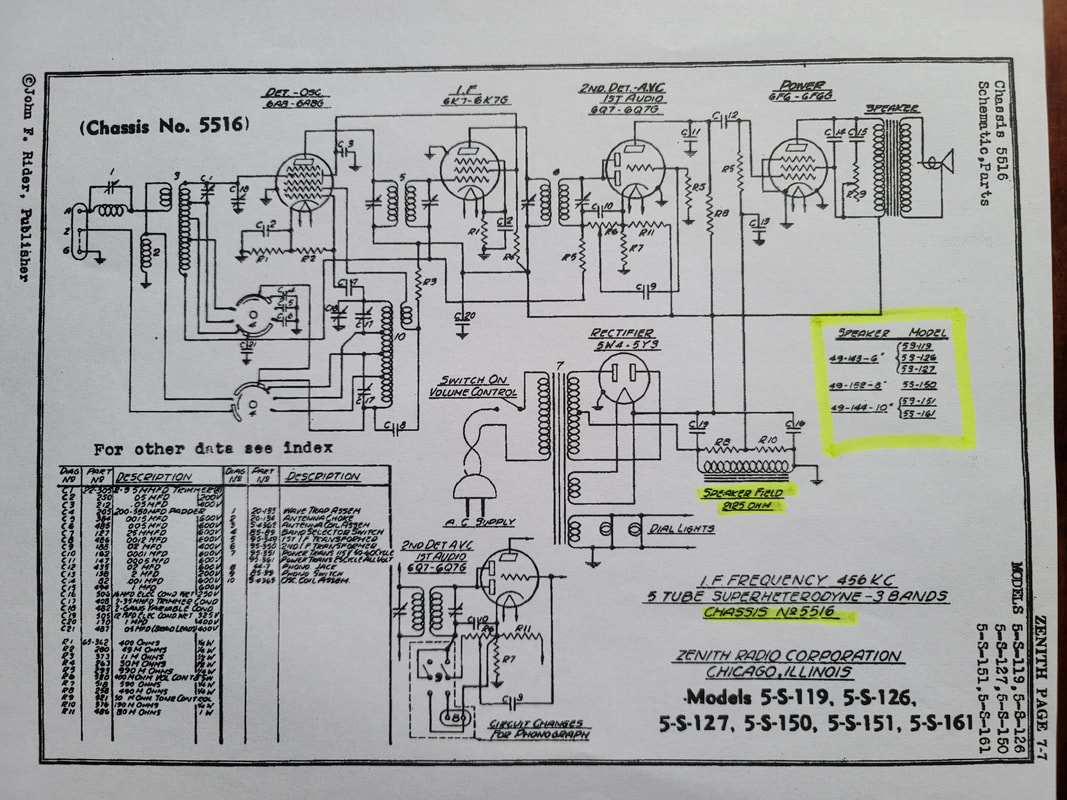

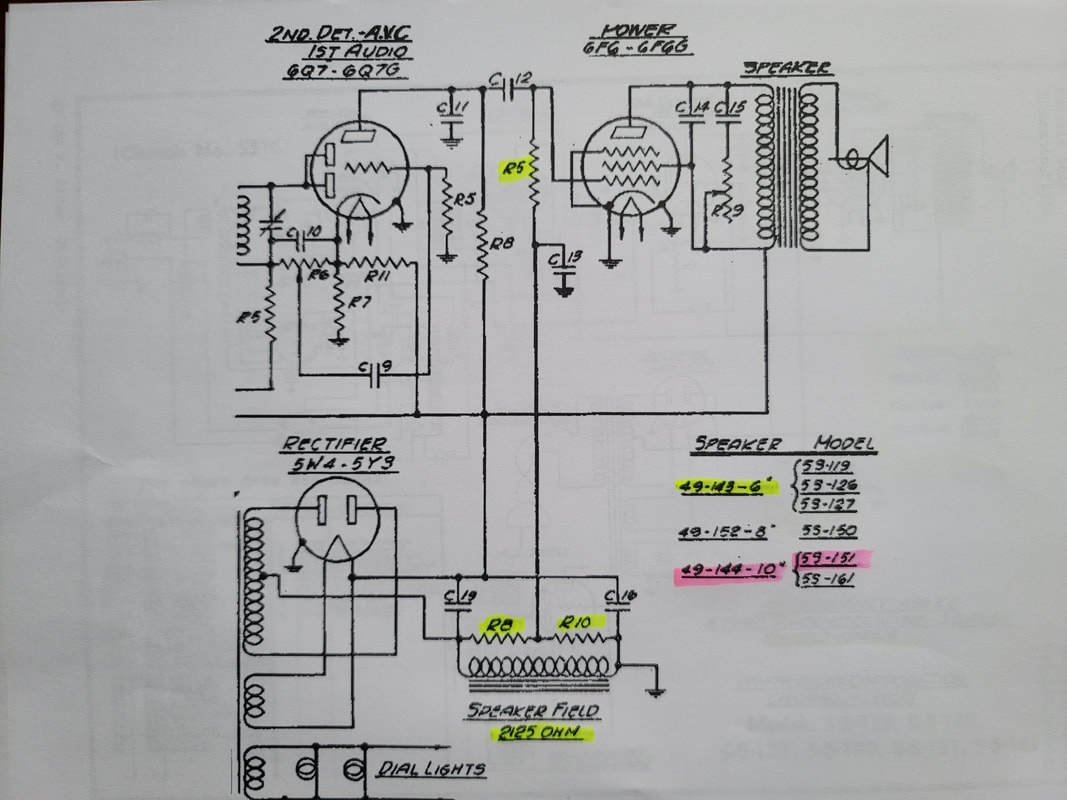

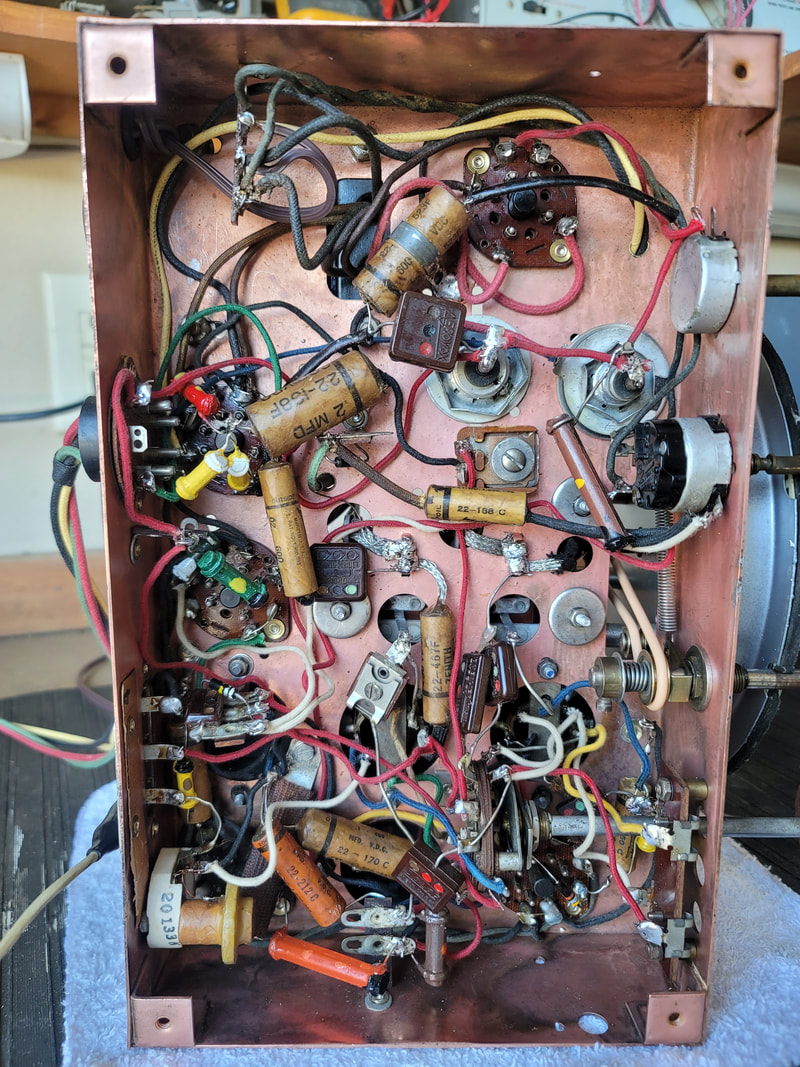

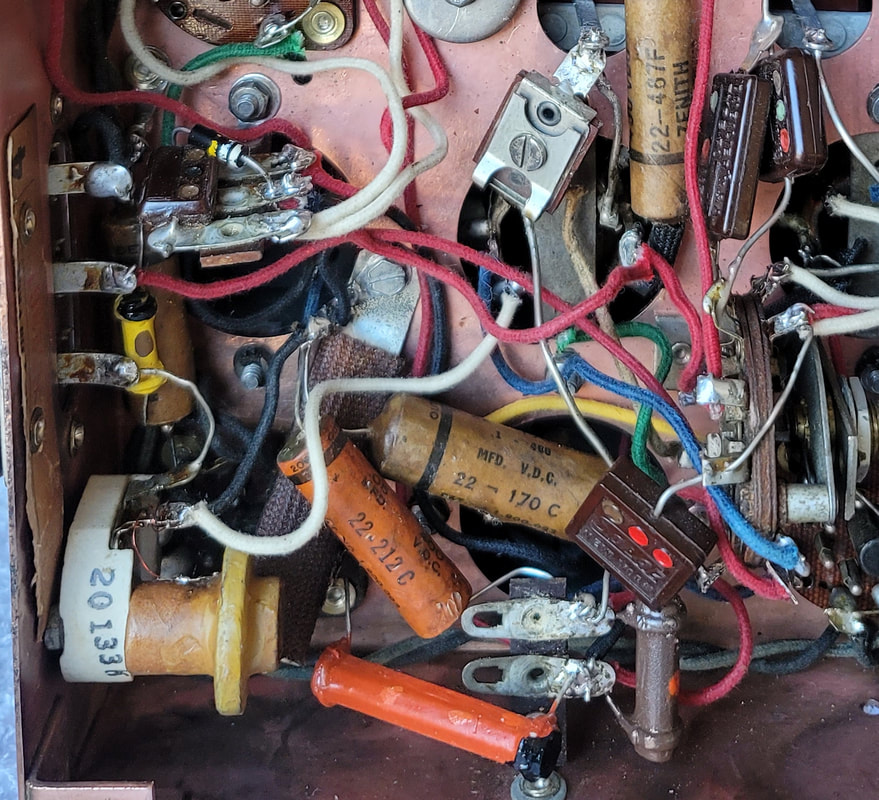

Below are pictures from projects, recently completed, for which I have not made posts. If you would like me to give further details about any of them , comment at the bottom. I might be able to go into further detail and pics. I highly recommend the OTL (output transformer-less) amp. It's performance is just amazing.

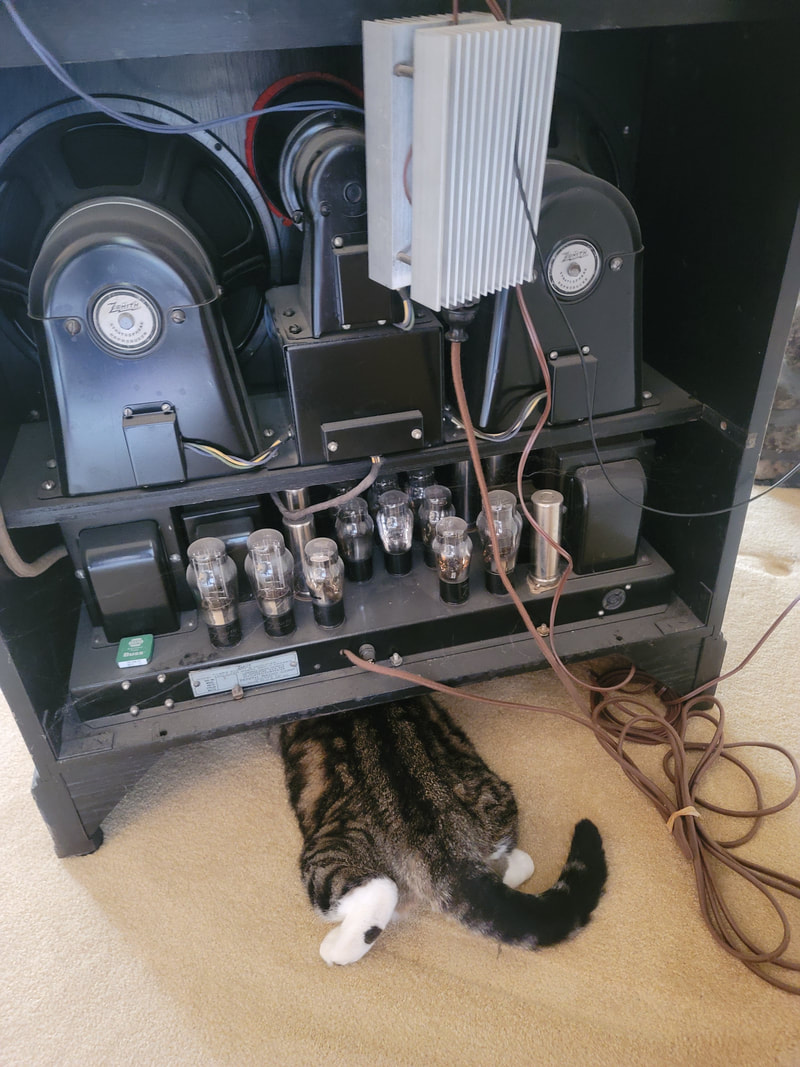

So I set up a production line and made a few (8). The sides are solid 1" mahogany that I milled from raw planks, which I could get and could get at a reasonable price - just more work and a lot of chips. The tops are mahogany veneer on Baltic birch plywood and they will slide out the back so the radio can be serviced (tubes) without removing the cabinet.

CV-295 Bird's eye maple cabinet

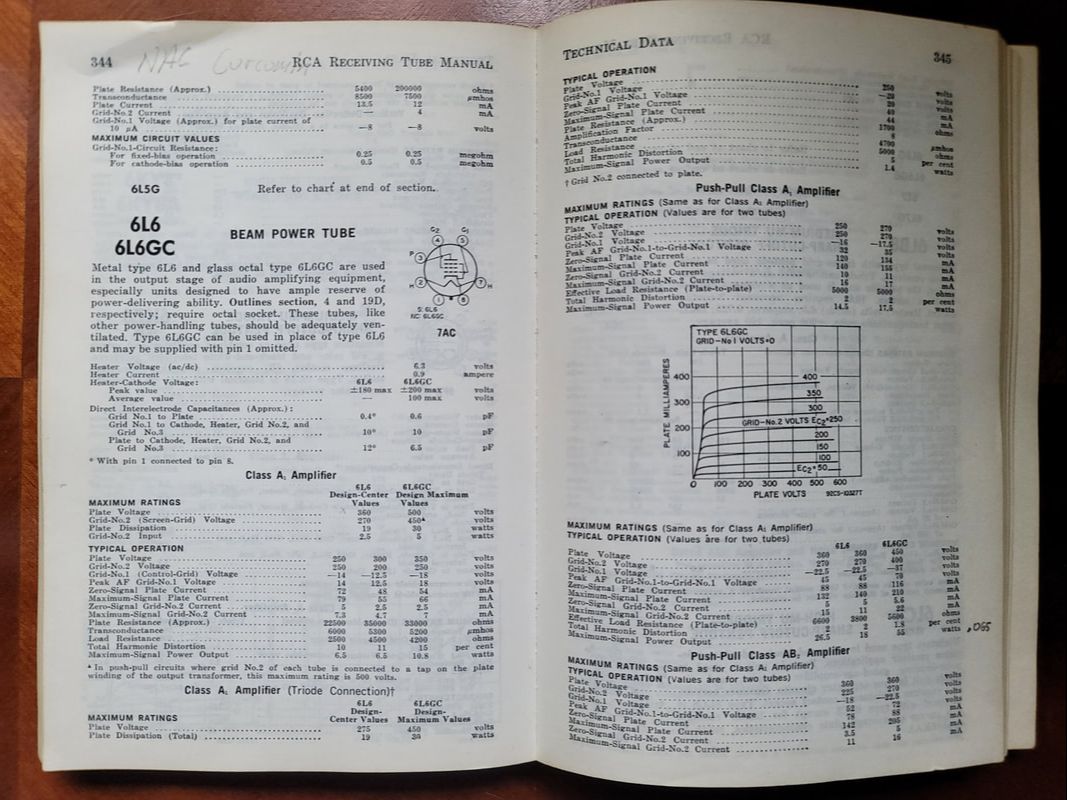

I had heard that these are not audio tubes.

Yes, it is built on a sheet of plastic. Very quiet - until you turn it up, with no hum from the regulated power supplies.

New kitchen.

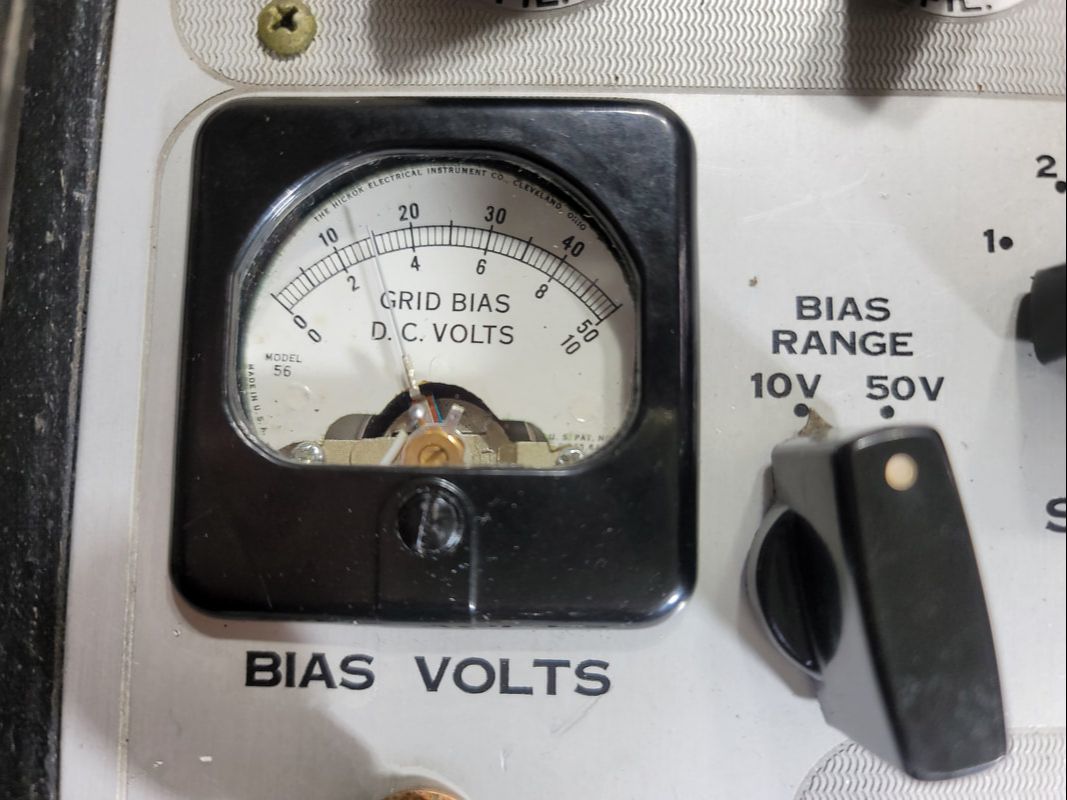

When I went to school (EE. Rolla MO.), what I REALLY wanted to learn, was how to build my own amplifiers - well - and to get a job to pay for them. In the following 50 years, there was always something else to do. But I collected a lot of parts, like 6080 tubes (6AS7). A SUPER TRIODE, that is only used in power supplies (frowney face 😉). Yea, right!

Also serves as emergency heater. Yes, it has a "warm" tone. Freq response from about 5hz to 100khz or more. It would go down to DC but I thought it would be better to prevent that from happening.

I needed to get the signal from my music server across the room to the OTL amp. Though I ran all of the wire I thought I would need when the shop was built, the best I had here was 2 twisted pairs from an old S- video cable. Needed to boost the level to drop the noise floor and balance the line into the 12AX7 first stage of the amp. It also provides remote volume and balance with a slight loudness curve to compensate for losses.

AGAIN with the "these are not audio tubes" thing.

As a result of the clearing needed to control wildfire, weeds were removed and the ground was exposed. We began to find arrowheads around the house. Compared to those I found as a kid in MO these are tiny and very intricately carved- and mostly broken, but still very cool.

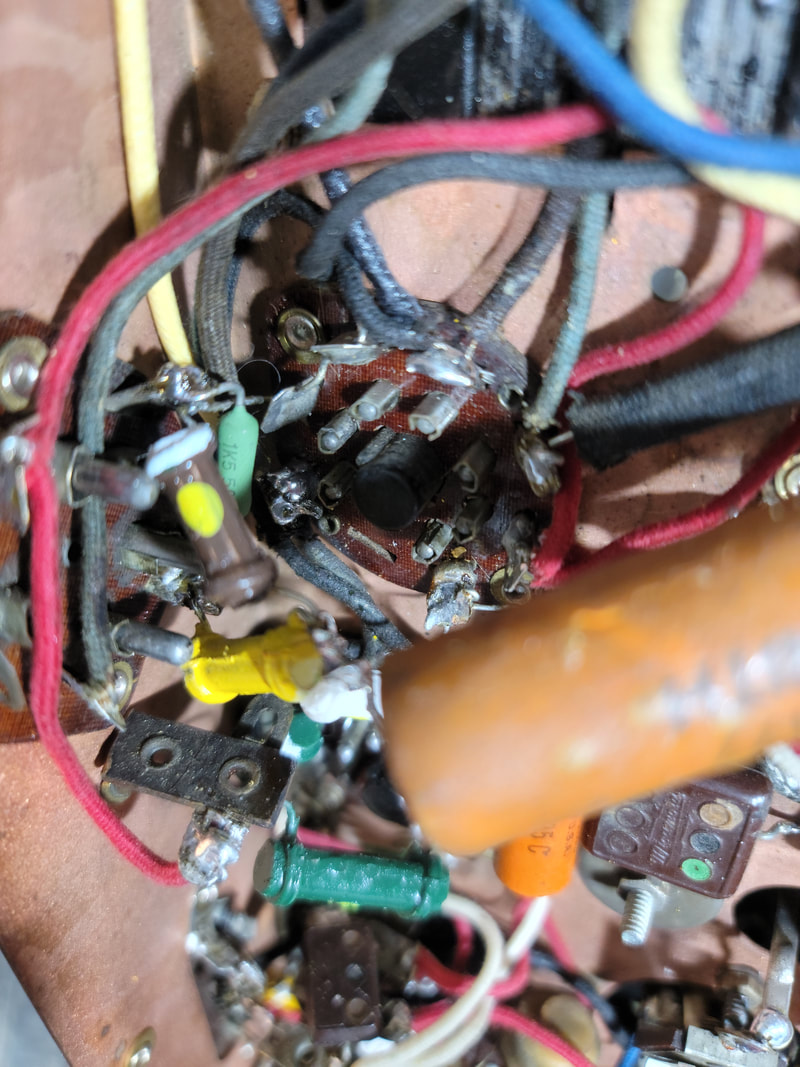

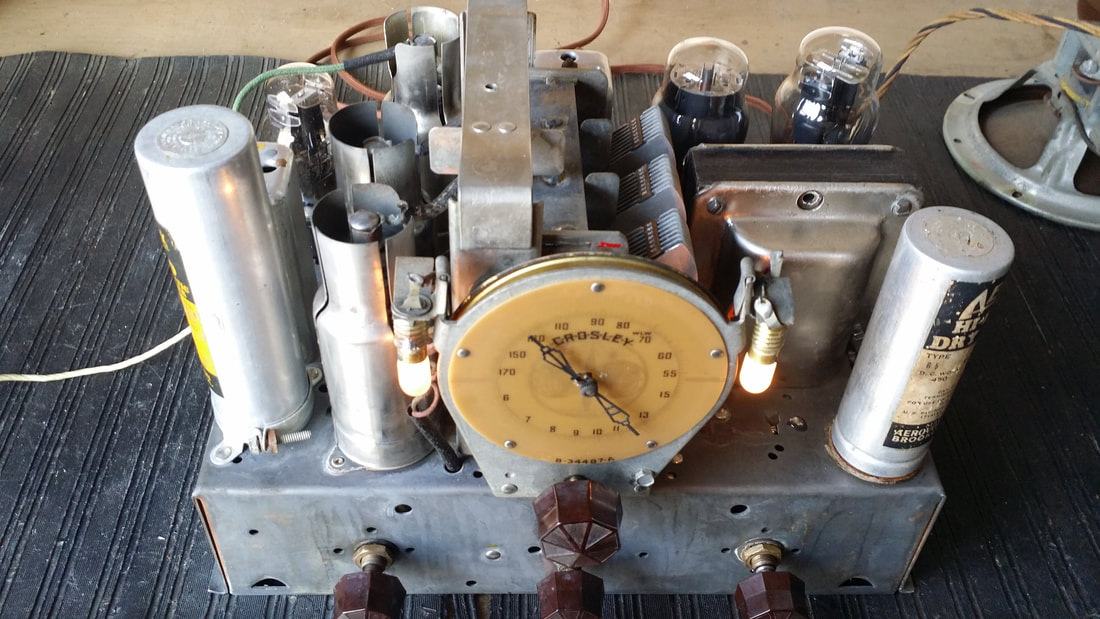

Finished. Yeah, that Solar cap was not original.

Ridin' The Storm Out

RSS Feed

RSS Feed