Some of Jerry's radios had the unfortunate luck of being exposed to moisture when a fir tree limb punctured the roof of his two-story shop. I believe that this AK 559N was among them.

As you can see from the BEFORE picture (above left) there was significant damage to the cabinet. This added to the fact that restoration of most 1934 Atwater Kent chassis is always a big job pushed this project towards the parts pile. But I also knew how nice it could be.

Anyone visiting the shop/museum has seen the "wood shed". Not used for fire wood (mostly), rather for wood and veneers used in cabinet repair and for parts chassis. The shed keeps the clutter down in the shop. There is room in the shed to keep a couple of cabinets. I usually decide right away if there is a future for most radios but sometimes a radio like the 559 gets disassembled, the speaker/chassis stored and the cabinet placed in this area. If it gets in the way, well, at least the veneer is salvaged. But sometimes (seldom) there will be a break in the demands of shop/house/tree farm and the project will be revived.

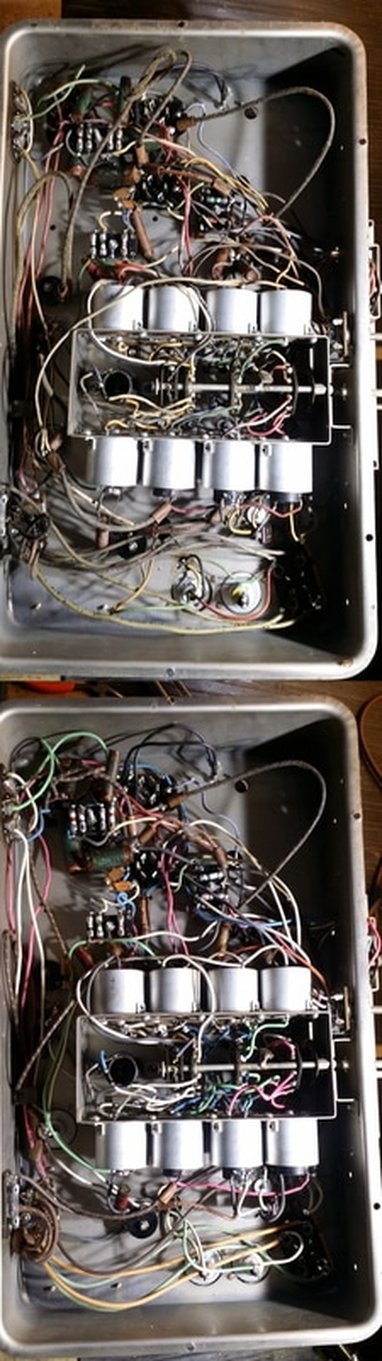

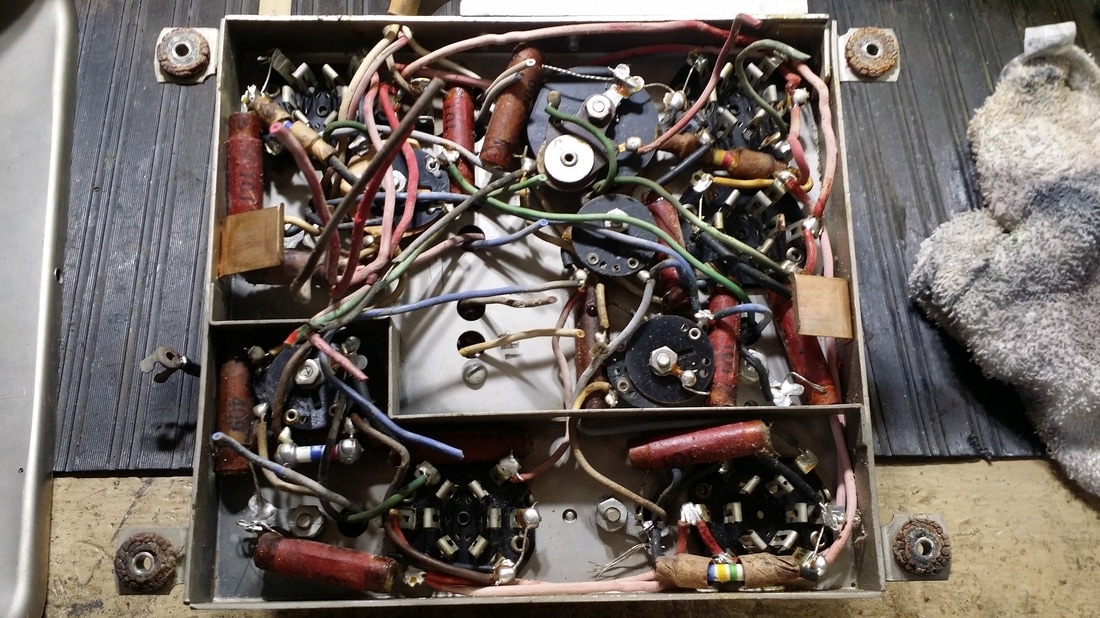

Above is the before and after shot of the underside of the 559 chassis. As always the objective was to repair damage/deterioration and find/replace missing original parts. The result should look like the chassis did a year or two after manufacture. (to look new most of these chassis would need to be replated, something that is done for high-end radios)

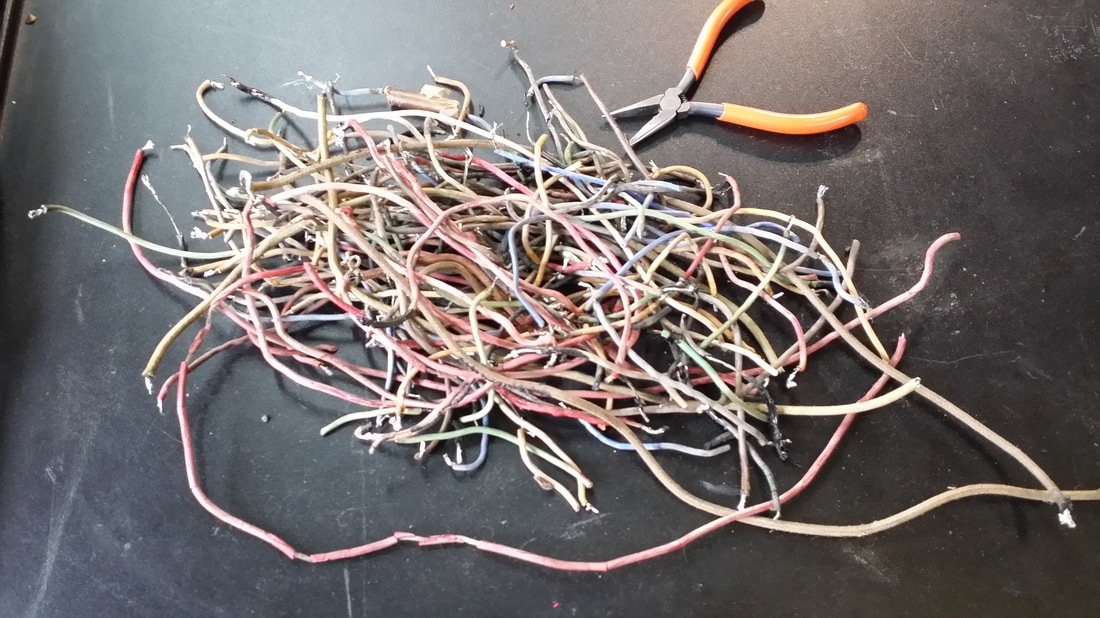

I usually move through a chassis like this servicing or replacing all of the parts hooked to a lug at one time. Often this will result in a lot of parts being pulled out at once. I have a good memory and schematics help a lot but it is highly advisable to take a lot of pictures before and during the process. Most radios work upon completion. Once in a while there will be a miss-wired connection but this is so seldom that upon completion I just plug the radio in and begin alignment.

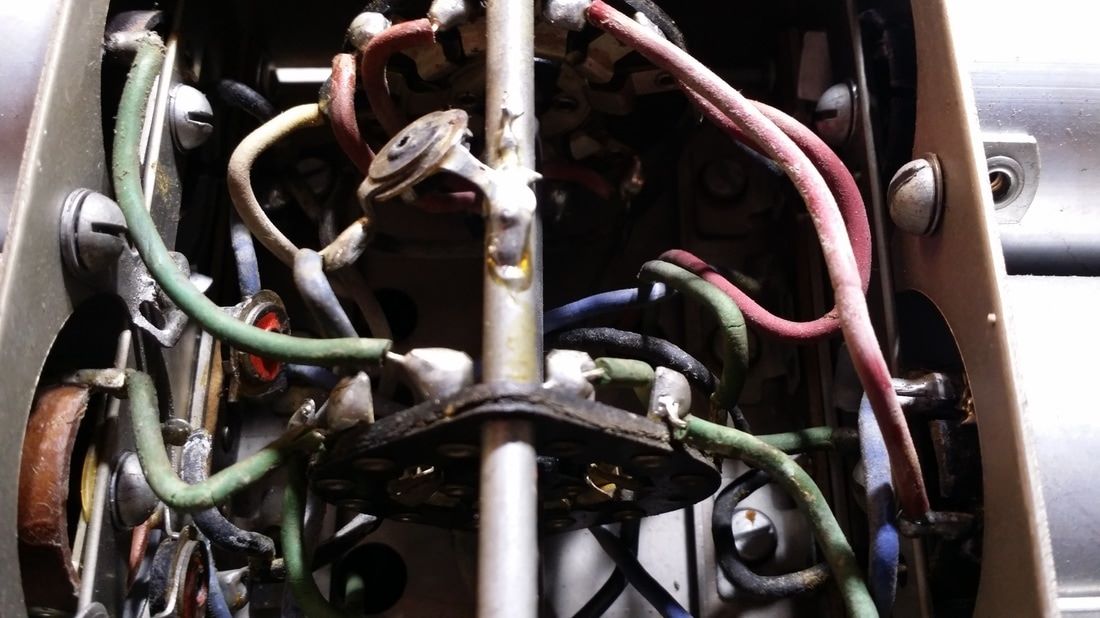

Above is the before and after of the rf/if chassis. At this point someone should ask if I know where all of those wires go.

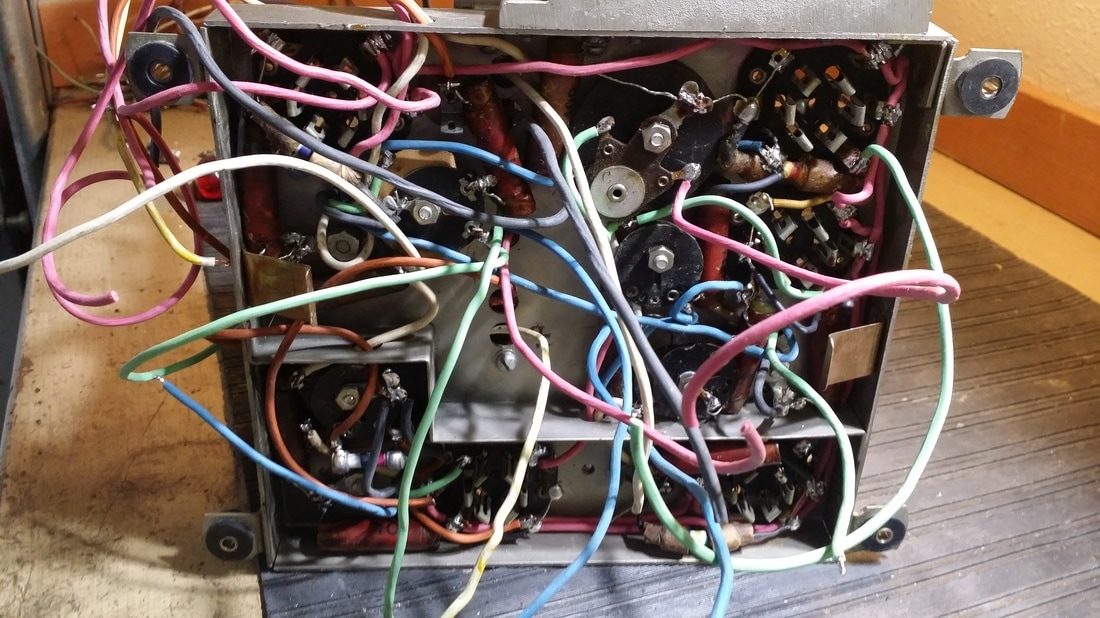

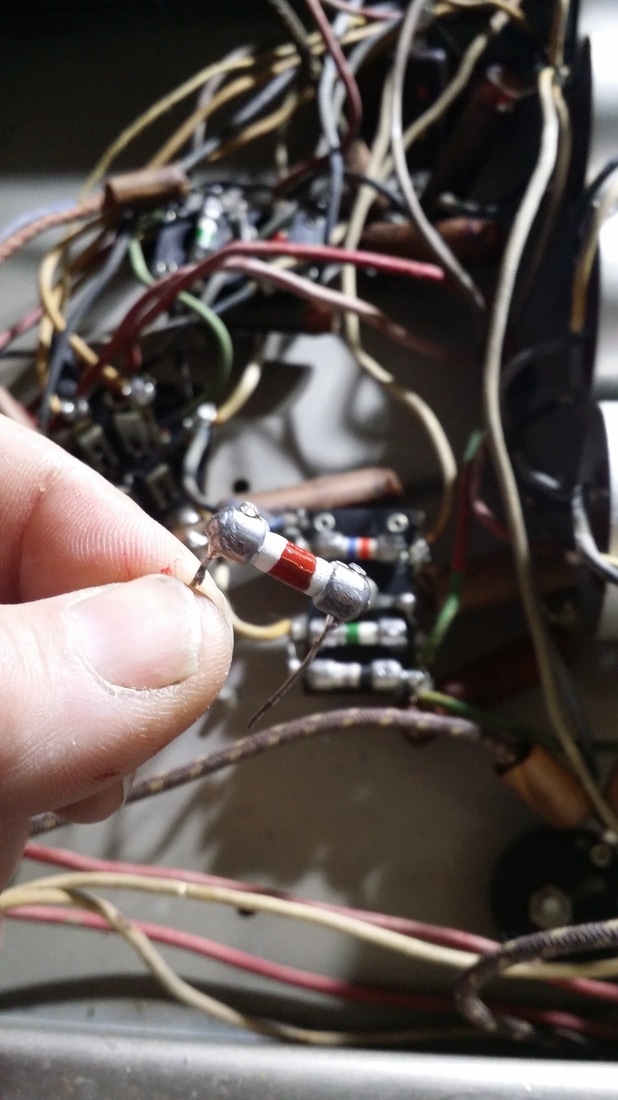

The styles of resistors used are either an early "dog-bone" or various wire wound types. In many radios the wire wound resistors, built on some form of substrate, have survived. AK built their WW resistors in the form of a flexible attachment that looks like a heavy gauge wire (right above). Many of these have not survived or have become intermittent. Unlike the types built with visible wire these corrode badly.

The dog-bone style types rely on a carbon rod inside of a ceramic holder with lead ends that make a mechanical contact with the carbon rod. This connection becomes intermittent over time.

The two examples above have been rebuilt. In the case of the WW resistor 4 or 5W modern resistors are hidden in the ends - usually in both ends - and the original cloth cover is slipped over a new wire connected to the new components. The old dog bones need to be drilled. A hole in the center of both ends allows the carbon rod and the ceramic to be driven out of the end. Care must be exercised so as to not damage the soft metal ends. A new 2 or 3 W resistor is covered with high temp spaghetti and soldered to the ends.

Here we have a piece of elm burl that can be used for replacement (not bird's eye maple).

RSS Feed

RSS Feed