I have accumulated quite a few late 20s metal box radios. All of them are very common. These radios are so common that shipping one usually costs more than the purchase price. So why is that? Well, besides them being popular in the 20s and having been built like a metal brick, nearly all of them have little chance of ever working again.

I have salvaged a few of these unfortunate specimens, but realized that the spare parts were only good for other unrepairable models. So why bother keeping the parts?

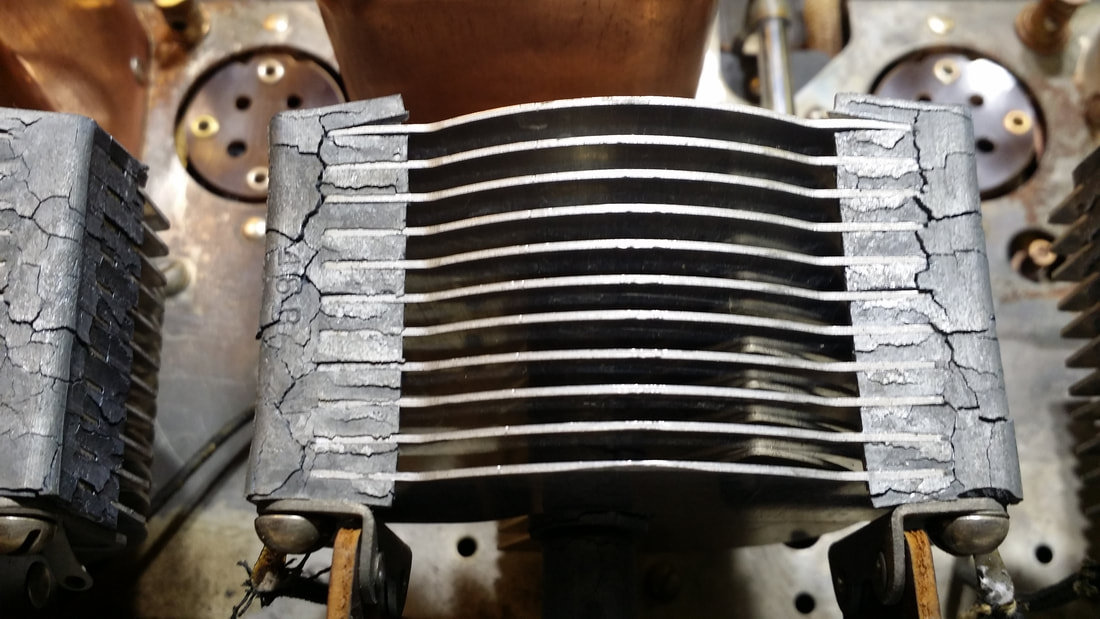

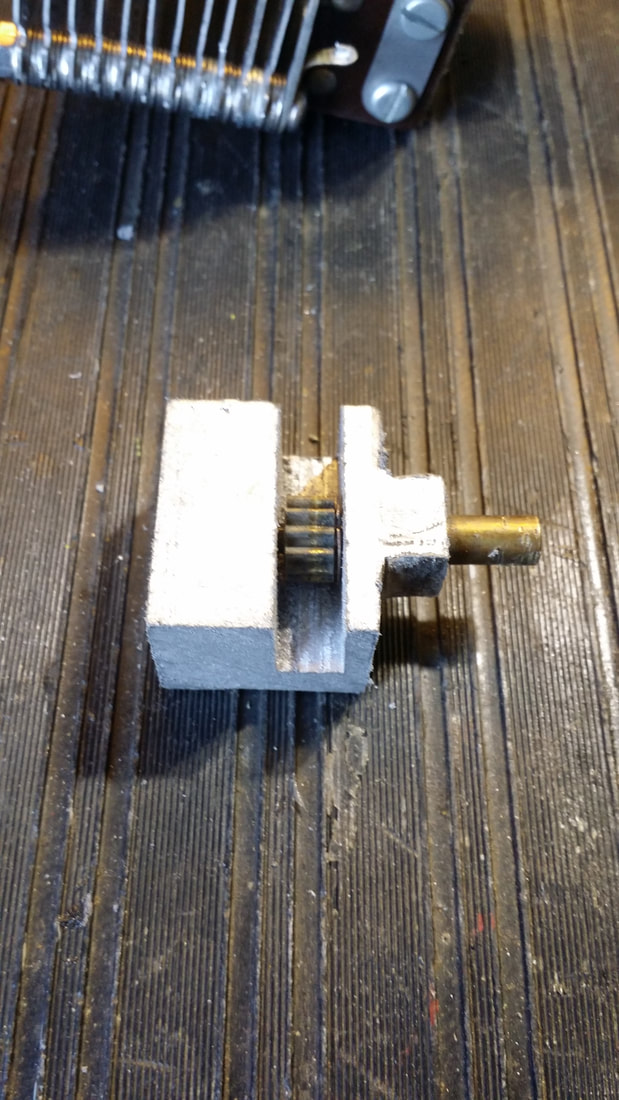

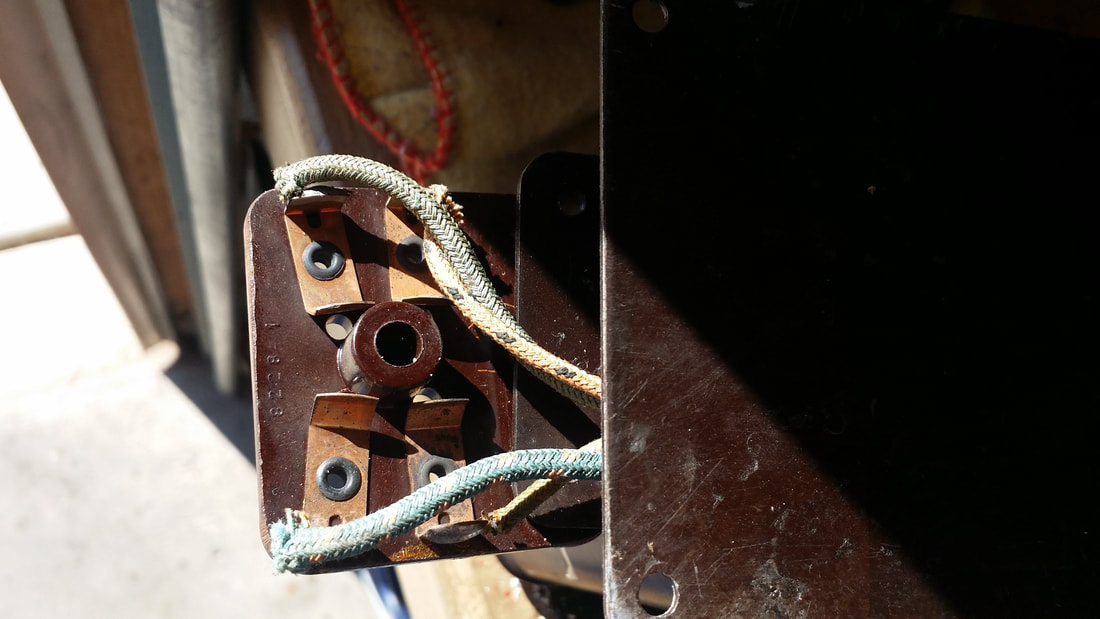

Below, the pot metal bracket, through which the rotor control shaft must pass, is also deformed and binding. Most of these look much worse than this one.

At the bottom of the picture are 2 plastic replacement brackets and one has been installed in the assembly (center).

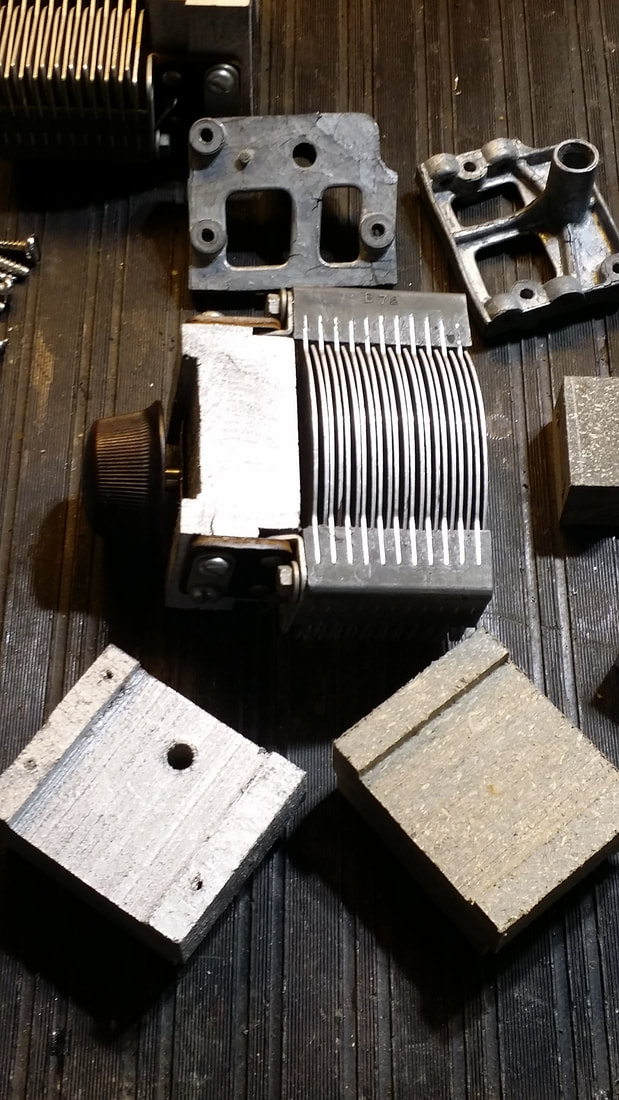

Since I had a pile of old deck material out on the "back 40" it seemed like a reasonable idea to give it a try. The old material that I had was an inch thick (newer material is only 3/4" thick and has a laminated wood-grain, not recommended). It is easy to shape on a table saw. It is easily strong enough and accepts wood screws, so the original machine screws/nuts will not be reused.

1. When cutting the brackets, shape the material in long strips. In other words shape the material by width and thickness, making all cuts possible prior to cutting it into equal length chunks. This will improve consistency.

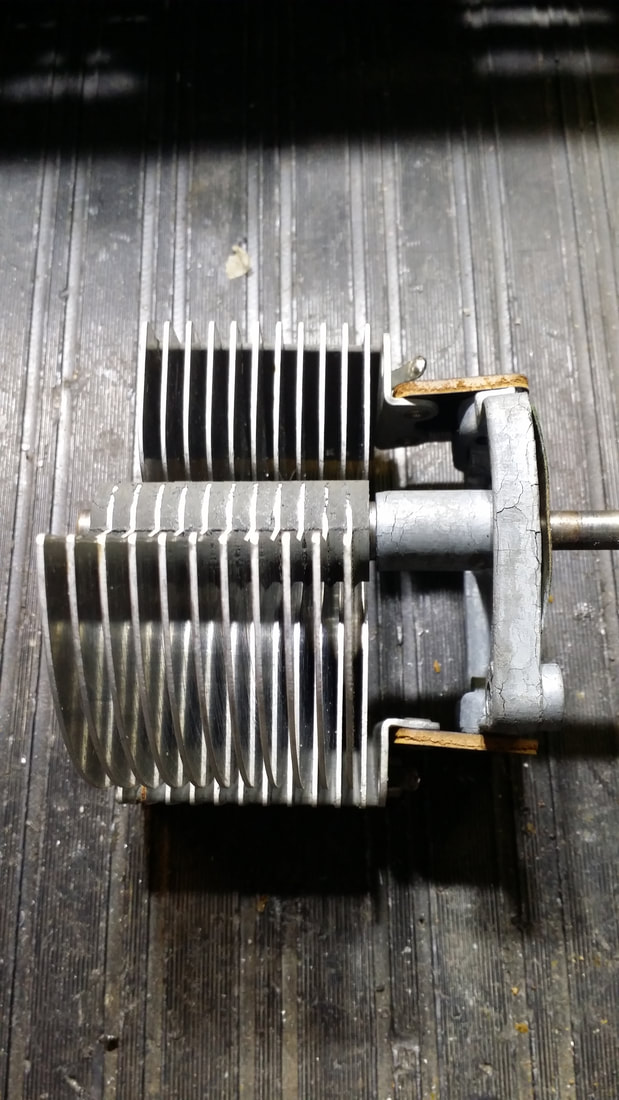

2. The hole required for the rotor shaft must be drilled on a drill-press. It must be accurate and STRAIT! Do not make it over-sized, just adequate for the shaft to be pressed through the hole. Note that the hole is off-center.

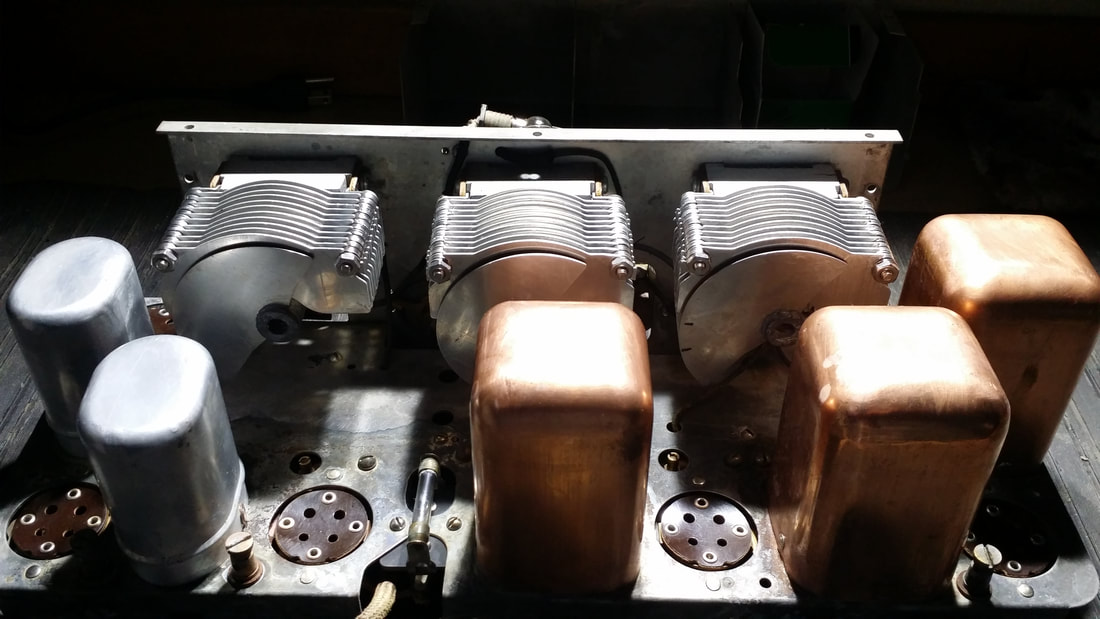

3. A ground must be soldered to each of the copper retaining clips shown above.

4 Make sure that each of the mounting screw locations is identical.

The solution to the tracking issue is to drill mounting holes into the center brass AK pulley and use it as well. The holes will have to be tapped to use the original hardware. Luckily the original Crosley bands are adjustable enough to accommodate the slightly smaller pulleys.

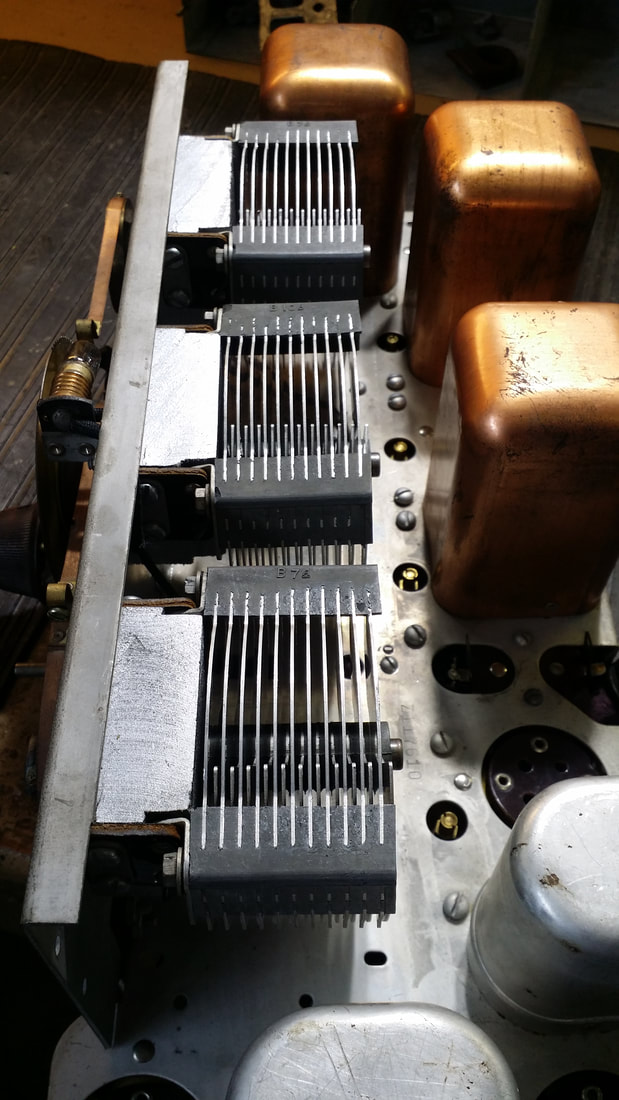

For some reason I found it easier to use these trimmers in association with the far right and left caps rather than the left and center as originally built. This only required moving one wire.

Shields must be in place for alignment. There is a lot of gain in this radio. Stage coupling is an issue. Mine work best with low value grid leaks ~ 1m or even less. The first tube is mostly used to decouple the antenna/ broadband RF amp. You might find that the radio works just as well with this tube removed. Not suggesting that you do that, just an operational note. I found that on strong stations I was running the filaments well below 5V. It also works well with B+ at about 65V and audio final B+ at about 90V so you can lower your C voltages as well.

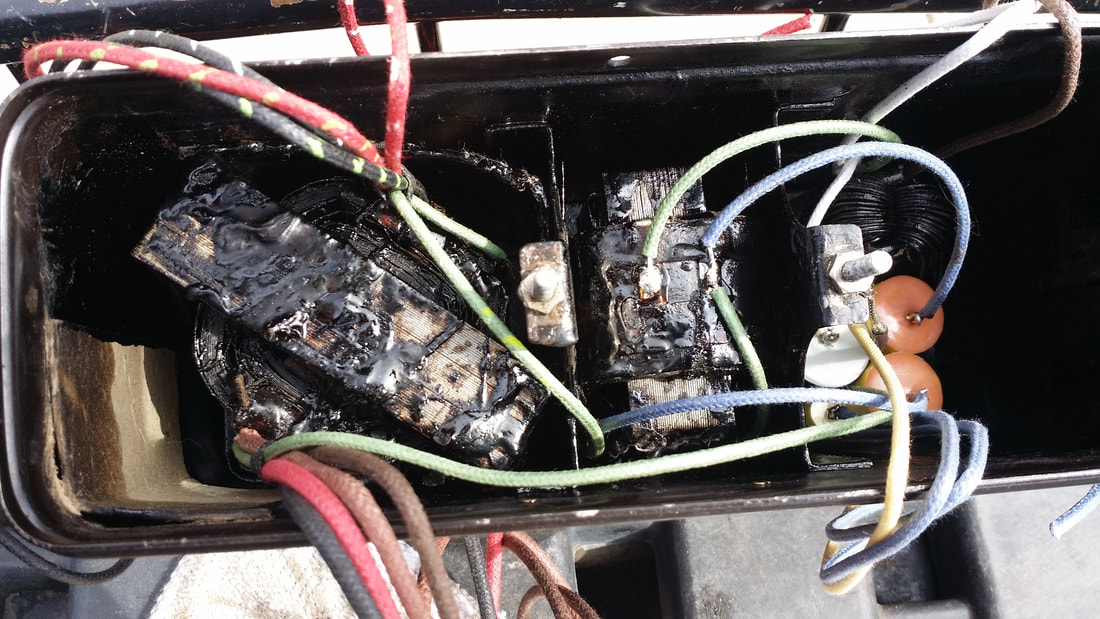

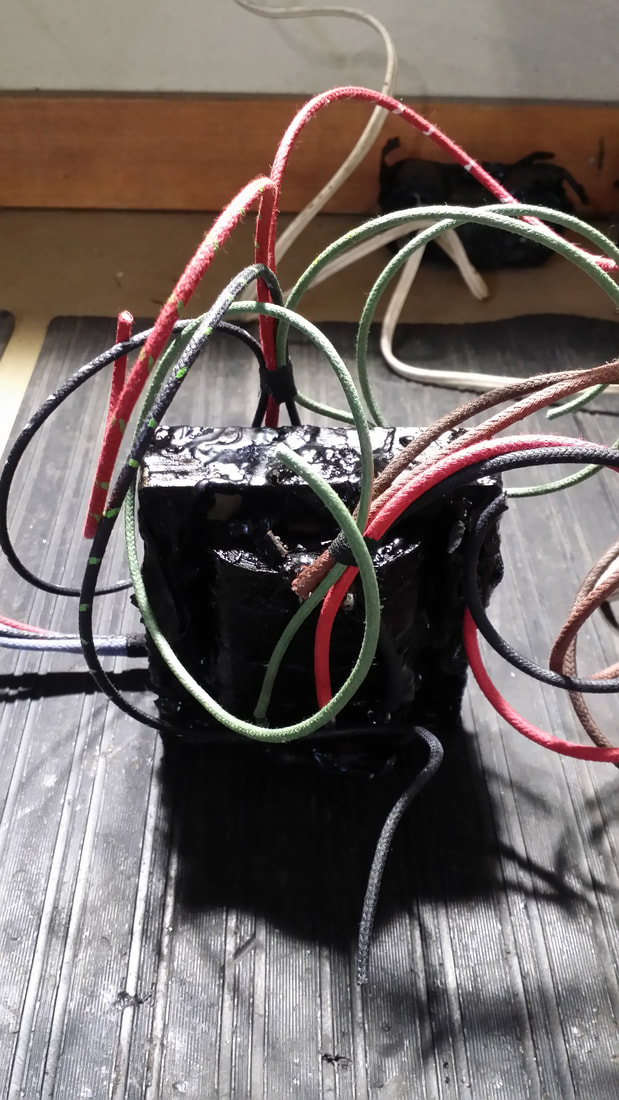

It seems that there is a radio-myth regarding the potted power supply that says that for some reason the filter caps are often good. This is just a fantasy. The effort needed to resolve this issue is beyond what most people want to invest in these rather common radios so it is easy to adopt this mistaken philosophy. The result is a radio with melted tar in the bottom and a failed power transformer - which leads to the second myth - AK power transformers are weak, which is also wrong. This, however, is a good way to end up with a parts chassis as was the case with several of the ones I had.

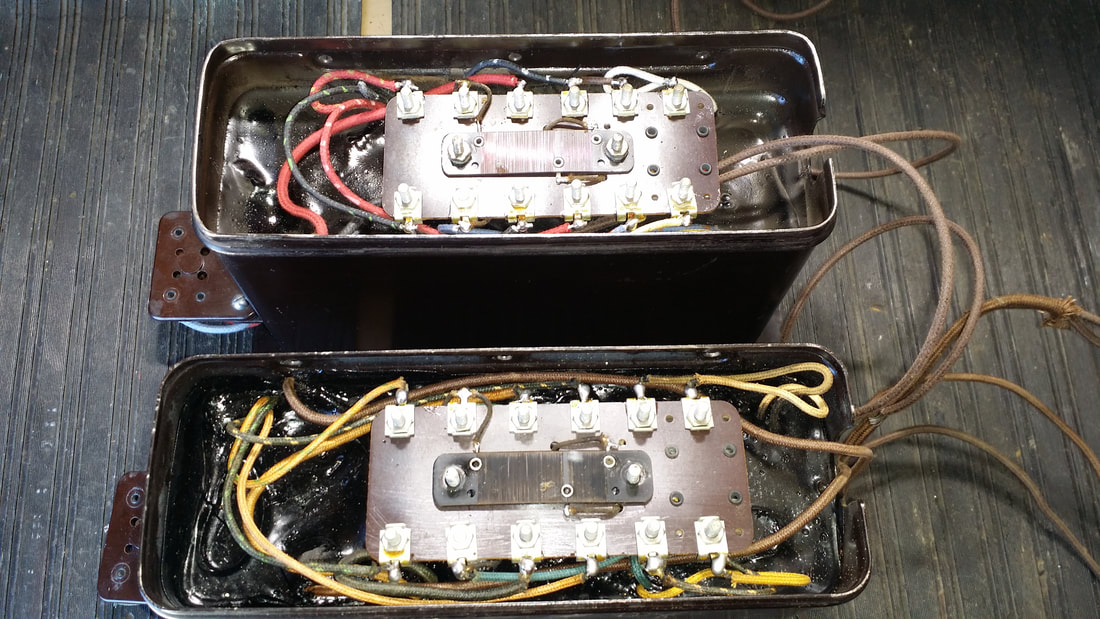

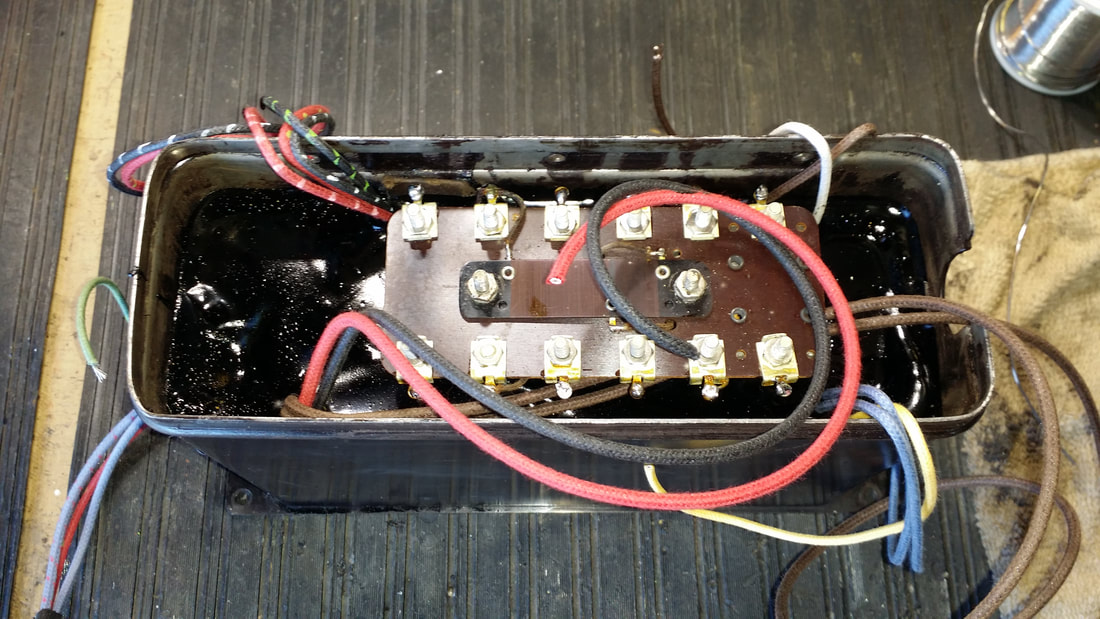

Below, you can see what is inside of the "can". The best way to service the filters is to gently warm the entire power supply can in an inverted position allowing the tar to run out into a metal container. Other methods usually result in damaged components. Only enough heat is required to melt the tar. This temperature is not high enough to damage the paint on the can.

Below you can see the components, rewired and repositioned in the can prior to replacing the tar. The 2 studs in the center are the ground. Sometimes it is best to bend these tabs upward to allow for easier passage of the components. It is always beneficial to remove the 2 nuts/bolts.

Another tip is to cut all of the wires as short as possible prior to melting out the tar. This is especially true of the wires leading to the rectifier socket. Also remove the cork found there.

It is easy to forget about the bypass cap that goes between contacts 3 and 9 since it is the only one that does not have a leg going to ground (and is not one of the filters).

RSS Feed

RSS Feed